Equipment

Supply

CresTechnologies are thermal processing engineers

and offer the best equipment:

• High Temperature Rotary Calciner

• Rotary Dryers

• Flash dryers

• Fluid Bed Dryers

• Spray Dryers

• Direct & Indirect Coolers

• Agglomerators / Granulators

Calciners

Are indirectly heated rotary furnaces that are designed to heat treat

a product by controlling the environment and the temperature the powder

is being exposed to

Why use a Rotary Calciner

• Indirect heating so the product is not in contact with combustion

products;

• process temperatures up to 2100F;

• products environment is controlled to achieve a special atmosphere

such as oxidizing, reducing or inert;

• multiple heat inputs for temperature profiling;

Typical products/industries for a rotary calciner

•

Catalysts

• precious metal recovery

• ceramic & rare earth powders

• carbon regeneration

•remediation

Rotary dryers are direct heated rotating cylinders where the feed material and drying gas come in direct contact. As the dryer rotates, the feed material is lifted and cascaded thru the drying gas; thus being dried. The drying gas is typically combustion products from a fossil fuel burner or heated air from a heat exchanger or tertiary heater.

The rotary dryer is used when the powder needs longer retention times to dry and requires agitation to enhance moisture removal or prevent "clumping." The tumbling action of is conductive to handle wet sticky materials.

Why use a Rotary Dryer

• efficient way to dry large capacities;

• product is not fragile;

• product can come in contact with drying gas;

• medium retention times (less than 90 minutes);

• product has coarse particle size;

Typical products/industries for a rotary dryer

• bulk chemicals

• ores and minerals

• coarse powder metallics

• salts and earths

Flash Dryers

A flash dryer is a pneumatic conveyor dryer. Traditionally oriented vertically, like a chimney, the drying column passes hot high velocity gas up through it. The wet feed is introduced at the bottom of the drying column and drawn upwards by the fast traveling gas. Simultaneously, as the wet powder is conveyed, it is dried rapidly thus cooling the gas by the evaporating moisture. By the time the gas and powder reach the top of the column, the material is dried and the gas is cooled sufficiently. They are separated by a cyclone or baghouse collector.

The flash dryer can be thought of as a high velocity fluid bed, where the gas is at such a velocity that it entrains the powder and carries out of the drying chamber.

Why use a Flash Dryer

• efficient way to dry high surface moisture powders;

• short retention times (seconds);

• excellent way to dry temperature sensitive products quickly;

• powder should be non-abrasive and non-friable;

Typical products/industries for a Flash Dryer

• high moisture bulk chemicals

• foodstuffs and grains

• fine chemicals and pharmaceuticals

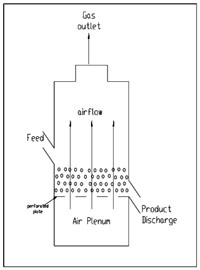

A fluid bed contains a circular or rectangular housing whose floor is a perforated plate. The wet feed is fed above the perforated plate and the hot gas fills the chamber below the perforated plate. The powder is fluidized, or aerated, by the heated gas passing through the plate and percolating through powder bed.

The fluid bed can be thought of as a low velocity flash dryer, where the gas is at such a velocity that the product is not pneumatically conveyed out of the drying chamber. The material is collected at the end of the chamber, while the drying gas is drawn out the top of the chamber

Why use a Fluid Bed Processor

• excellent contact between powder and drying gas;

• aeration process enhances maximum particle exposure;

• low temperature drying suits temperature sensitive materials;

• gentle, continuous bed activity;

• medium retention times (less than 30 minutes);

• cross flow heat transfer between the powder and gas yields high thermal efficiency;

Typical products/industries for a Fluid Bed Processor

• coal

• plastic

• pharmaceuticals

• ceramics

Spray Dryer

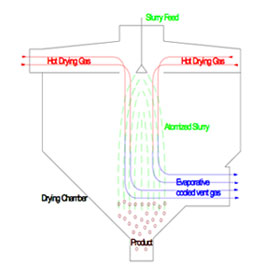

A spray dryer is a dryer for liquids with dissolved solids, low viscosity slurries and paste. It works on the same principles as another dryer, the flash dryer. The liquid feed is atomized into droplets and dispersed into a hot gas stream. The water in each droplet is evaporated leaving behind the solid residue as product. The evaporated moisture mixes with the incoming hot gas and leaves the dryer as a cooled vent gas.

The droplet size acts like a boundary for the precipitating solid, thus the droplet size and droplet distribution governs the particle size and distribution of the powder. Typically, the resulting powder shape is spherical and the particle size is fine (below 100 microns). It is recommended that if a particular size and distribution is desired, a spray dryer is used. If removal of moisture is the only goal, concentration and traditional solids drying is a viable alternative.

• excellent way to dry a liquid feed with dissolved solids;

• achieve a particular average particle size;

• achieve a particular particle size distribution;

• enhance flowability

Typical products/industries for a Spray Dryer

• dairy products

• agricultural chemicals

• fine grain pigments

• soluble pharmaceuticals

CresTechnologies’ line of direct coolers consist of all dryer styles whose heated drying air is replaced with cooling ambient air. Thus our rotary cooler operate in parallel and counter-flow modes, where the cooling air pass in the same direction as the advancing powder (parallel flow) or in opposite direction as the advancing powder (counter-flow). Our fluid bed coolers are almost exclusively rectangular.

Our line of indirect coolers use water as the cooling media. The two styles are a water spray cooler, which sprays water onto the shell exterior which is heated internally by the passing hot product. The water tube cooler is a rotary heat exchanger style, where the cooling tubes are filled with water and cool the material as they pass over them.

Agglomerators / Granulators

To complete our process line, CresTechnologies supplies spray and roll compaction agglomerators, also known as granulators, through third party sourcing. Although the equipment is manufactured by a third party, the equipment and process is engineered, serviced and guaranteed by CresTechnologies, Inc.

Agglomerators increase particle size either by spraying a binding solution onto the particles and building a larger particle by adhesion (spray granulation); or by pressing the particles together so their surface asperities lock together to form a larger “puzzle-like” flake (roll compaction). Traditional drying methods with agglomeration supplement as well integrate particle morphology with spray drying technology.

Why Granulate

• increase flowability;

• decrease dustiness;

• increase solubility;

• increase dispersion;

• decrease segregation (due to settling of fines)

Typical products/industries for a Spray Dryer

• Nutritional additives

• Pharmaceuticals

• Pigments

We are thermal processing engineers and offer the best equipment:

High Temperature Calciners

Spray Dryers

Rotary Dryers

Fluid bed Processors

Flash Dryers

Indirect and Direct Coolers

Agglomerators

Equipment Modernization

At many facilities, the production is operating on outdated equipment or eclipsed technology. Although the operation is reliable and proven, the production is inefficient and costly. This is because equipment safety factors to insure satisfactory contractual obligations.

Now tap into that safety factor and possibly achieve 5% to 15% additional production by allowing CresTechnologies to modernize your aging system. We start by inspecting the system and obtaining key operational factors; we then apply these factors to our in-house computer models to see if the

operation can be modernized economically. The result to our Client is a renewed production that can operate under the rigorous 21st century demands. Through our modernization program, our Clients’ existing production lines have seen:

• 18% production increase to a plastics manufacturer by increasing the airflow through their dryer;

• 7% production increase to a catalyst manufacturer by adding shell internals to their dryer;

• 28% production increase to a bulk chemical manufacturer by increasing the temperature of drying to their flash drying system;

• 22% decrease in production cost by adding heat recuperation to their furnace stack;

• 5% decrease in downtime by upgrading the process controls from discrete controllers to an integrated control logic scheme. This increased production by 1 shift per week by better handling product transfer and storage. This increase represents 18 days of additional production.

Replacement Parts

CresTechnologies keeps your equipment running like new with qualified replacement parts. We supply any and all parts for your production system. To mention a few:

• Replacement shells

• Seals

• Gearing and drive components

• Refractory and Insulations

• Rolling components (trunnion / thrust rolls)

• Controls and Mechanical parts

Replacement shell of higher alloy material allows the Client to operate their unit at a higher temperature to increase capacity.

Replacement trunnion roll assemblies with boron surface treatment to withstand abrasion from the plant’s dusty atmosphere.

Replacement breechings with bellow seals allow the Client to run a specialized atmosphere in the unit.

Pumping station was packaged on a skid to shorten installation time.