CresTechnologies understands that your company has some of the best engineers

and scientists with unparalleled experience with your products. However,

in these modern times they are focused on present production needs to

meet your ever demanding customer. With these demands requiring full time

attention, your company process development projects may be slow moving.

This is the time you need CresTechnologies.

CresTechnologies' process development capabilities have helped many companies

maintain their marketing edge by assisting, supplementing, managing, or

assuming full responsibility of the development project. Our capabilities

include:

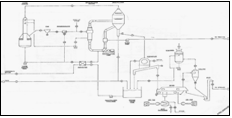

Flow-sheet for liquid concentration line

• Process modeling

• Pilot plant testing

• Product testing

• Small batch production

• Process Optimization

• Contract Manufacturing

When CresTechnologies assists you in your process development program,

the projects progress smoothly and seamlessly each step of the way. When

one Client wanted to implement a liquid concentrate line to enhance their

vitamin supplement product mix; CresT conceived the production line through

our process modeling services and then pilot tested its feasibility through

our pilot testing service. After those phases were successfully completed,

CresT prepared small batches for distribution to our Client’s customers.

After that, we provided temporary contract manufacturing to build demand

while the plant was engineered and built through our engineering and construction

services.

Bench-scale liquid concentrate line

Indirectly heated laboratory calciner

And

our capabilities continue with our other systems. We also model, test,

engineer and supply:

• Rotary Dryers

• Flash Dryers

• Fluid Bed Processors

• Spray Dryers

• Indirect and Direct Coolers

• Agglomerators

Pilot size spray dryer